TECHNOLOGY

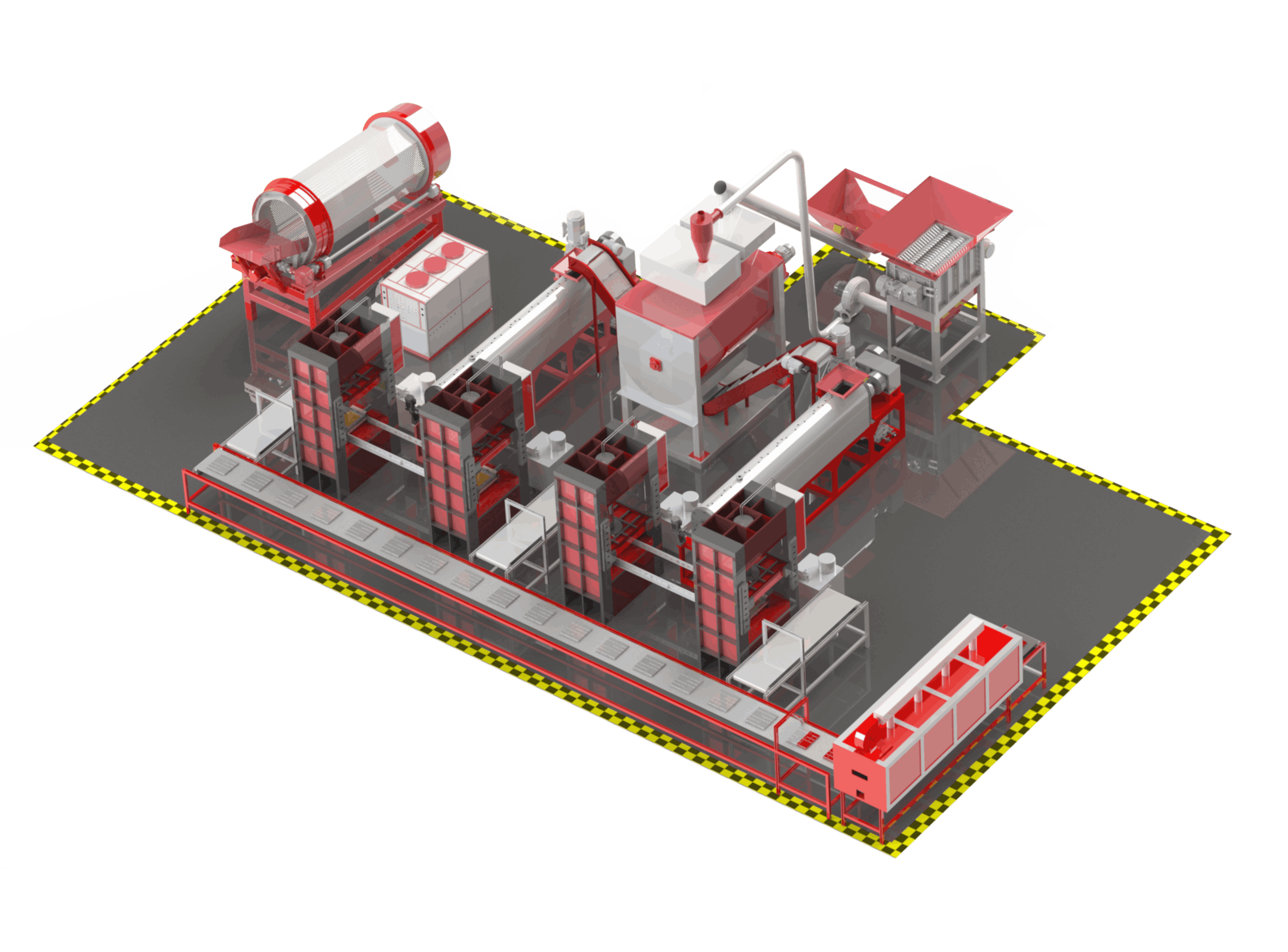

POLYMER COMPOSITE TECHNOLOGY

Aggregate Siever

Plastic shredder

Aggregate Conveyer

Plastic conveyer

Ribbon Blender/ Mixer

Feed Conveyer

AHM

Hydraulic press

Auto die Feeding System

Product Conveyer

Finished Product

Spray coating Point

Product drying chamber

Our patented recycling process turns waste materials like single-use plastics, construction and demolition debris, and industrial mineral, aggregate, and ash wastes into sustainable polymer composite materials, with properties not typically found in traditional materials. The material is created as a result of the filler/aggregate and polymer being uniformly mixed at the designated temperature regime by a MECH-THERMOFUSIONÔ process, which causes each filler particle to absorb polymer. The aggregate mass polymer provides a homogeneous monolithic structure with outstanding strength during further molding and hardening.

Our air-based separation systems provide convenient waste recovery and sorting options, making the process efficient and cost-effective.

SPECIFICATIONS:

- Material Processing Capacity: 1 to 1000 TPD

- Input: Plastic Waste, Recovered Aggregates (C&D), Ash (BF, Bottom, Fly, Pond, Boiler), Dust (Quarry / C&D), Dry Minerals Powders (Marble, Ceramic)

- Output: Polymer Composite Material / Products

50+

Type of Composite Products Lean Manufacturability

60 - 80%

reduced GHGs emission than EoL material processing tech

90%

less water required vis-à-vis to traditional recycling

3X

High Strength & 2X More Durability in Polymer Composite Materials.

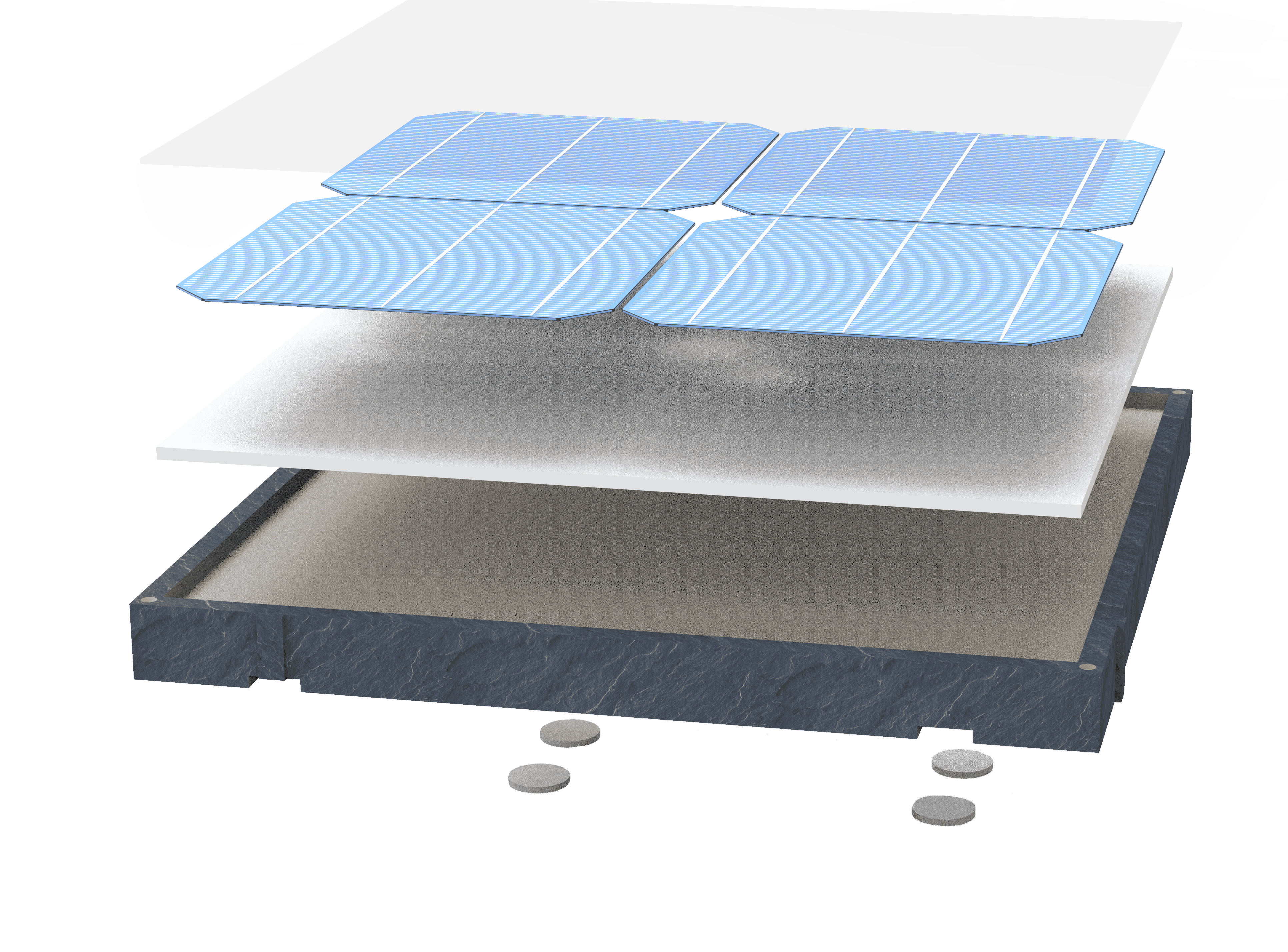

C- Building Integrated Photovoltaic technology

Anti slip-> Tempered glass

Solar cells

Insulated Panel

Aluminium Heat Sink

Recycled Composite Material

Connecting Terminals

Our Carbon Negative BIPV represents a ground-breaking approach to sustainable energy and architecture. products harness solar energy to generate clean and renewable electricity, reducing reliance on conventional energy sources. What sets our BIPV solutions apart is their carbon-negative nature. They go beyond mere carbon neutrality by actively removing carbon from the environment. Through their lifecycle, they offset more carbon emissions than they produce, making them an environmental win. This is innovation with a profound impact on the environment and the future of construction.

SPECIFICATIONS:

- Output Capacity: 1 to 100 Kwh

- Design & Installation: Interlocking & Modular

- Product Type: Pavement, Façade, Wall Tile/Brick

5X to 10X

Space Saving Solution

3in1

3in1 Solution (Energy Generation, HVAC Load Reduction & Water Proof Building Material)

50% to 80%

Reduction in washing & cleaning costs

Solutions for resource recovery that are affordable for the global recycling business. Our cutting-edge design for a material separation system and carefully engineered parts guarantee optimal effectiveness, speed up the sorting process, and raise both the quantity and quality of recycled material grades.

Our air-based separation systems provide convenient waste recovery and sorting options, making the process efficient and cost-effective.

SPECIFICATIONS:

- Material Processing Capacity: 5 to 100 TPD

- Input: Legacy Waste, RDF, MSW, Mix Dry Waste

- Output: Low Density (Plastics, Paper), High Density (Textile, Glass, Inert), Metals

2 to 50 mm

Output Material Size

300 to 2000 kg/m3

Wide range of bulk density material adaptability

Join us in building a circular economy

At Saltech Design Labs, we don’t just envision a better future; we’re building it. We invite you to join us on this visionary journey towards a more sustainable, innovative, and technologically advanced world. Together, we can reshape industries, solve environmental crises, and create a more sustainable, prosperous world for generations to come.